Electric Drive Motor Test

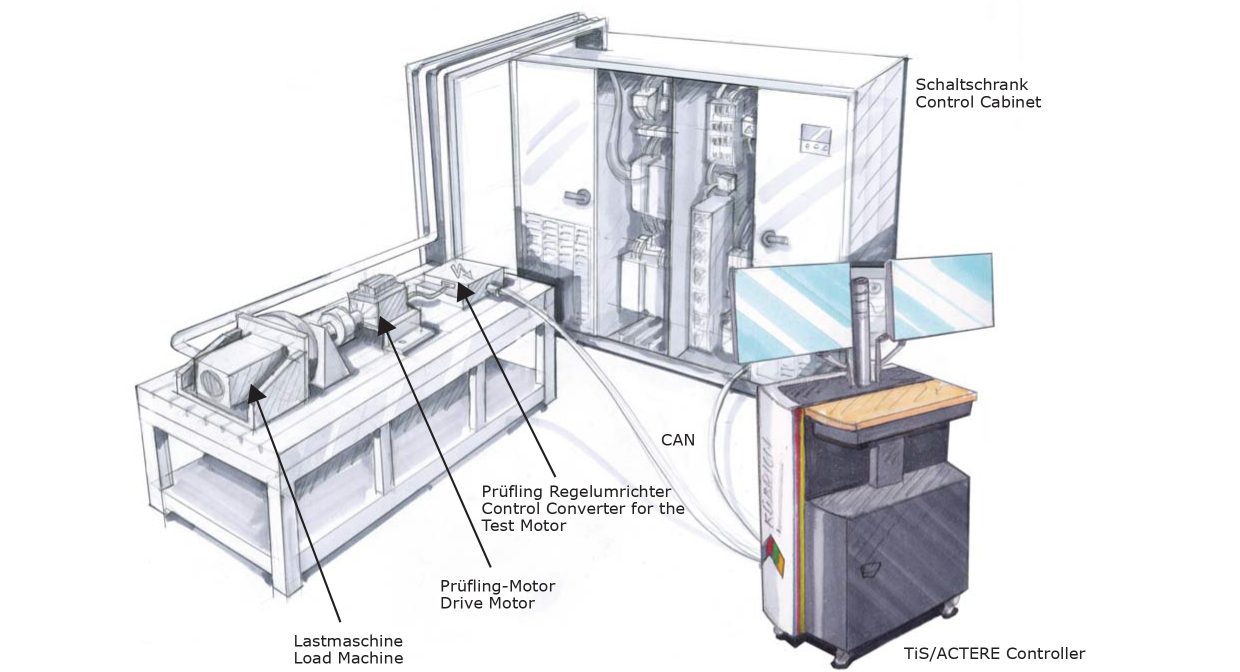

The vehicle conditions are realistically simulated by using a load machine and conditioning (cooling). A climatic chamber is therefore unnecessary.

The Kuebrich control system can be operated intuitively. Tests can be started manually or in automatic mode. Due to its open interface concept all common measuring instruments can be connected and integrated.

The evaluation of the measuring data goes smoothly and securely. The mechanical components of the Kuebrich test stands harmonize optimally with the control and ensure trouble-free operation.

To a large extent standard components are used – therefore you remain flexible for a long time.

Additionally, the energy recovery integrated in the system will save you costs. This test stand is manufactured by us and is successfully in use.

Measurement Technology:

– Torque Measurement Bar HBM–T12

– Performance Measurement at DC connection, AC Connection and on the Axle with Performance measuring Unit (e.g. Yokogawa)

– Flexible Number of Temperature Sensors for the Test Object

– Flow and Temperature Measurement for the Test Object Conditioning

– Cooling Unit Regulates the Coolant Temperature Available

Machine Bed:

– Pneumatic Suspension for Vibration Isolation > Prevention – of Building Damage

– Simple to Transport

– Low Requirements on Constructional Demands, no Constructional Changes Necessary

Battery Simulator:

Energy Compensation in DC Intermediate Circuit between Drive and DC/DC Convertor, Enabling Measurement of Network Connection and Input of

48V Starter Generator Test

Small Motors Test

Hybrid Power Heads

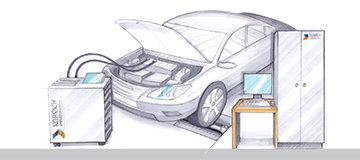

Electric Drive Motor Test

DC/DC Converter

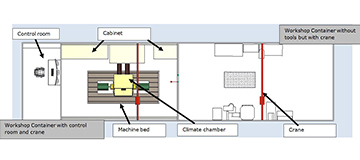

Container solution

Battery Simulation

Converter Test System

ACTERE